Product Introduction

Features of Micro-oil Frequency Conversion Screw Vacuum Pump:

★ The application of a new, self-owned patented energy-saving screw tooth profile provides you with a greater competitive advantage in the industry;

★ Using a vacuum-dedicated exhaust port and pressure point/flow path design, it can be used without an oil pump and maintain low vibration and low noise operation under high vacuum;

★ The tapered through-shaft screw rotor is matched with a high-efficiency permanent magnet frequency conversion integrated motor, reducing pump body vibration, greatly improving transmission efficiency, having a wide frequency modulation speed range, easy frequency conversion control, sensitive dynamic response, and enabling precise vacuum adjustment and reduced grid pressure;

★ Easily maintains stable high pumping speed under 2000Pa vacuum, stable negative pressure, with a maximum vacuum of 30Pa;

★ Can replace similar products in the market for rough vacuum applications, especially liquid ring pumps, rotary vane pumps, claw pumps, and piston pumps, with energy savings of 30%-85%;

★ More efficient and energy-saving: integrated screw energy-saving host, permanent magnet frequency conversion system;

★ More stable and reliable: quiet and low vibration, convenient replacement, ultra-low oil content, reduced pollution;

★ More intelligent and user-friendly: linkage control, early warning prompts, cloud internet;

★ Lower noise: vacuum performance test, durable and reliable, independent air duct, overcoming various operating conditions.

Comprehensive Performance Comparison

|

|

Water Ring Vacuum Pump |

Screw Vacuum Pump |

|

Vacuum Pressure |

Ultimate Vacuum 3300pa |

Ultimate Vacuum 60pa |

|

Environment |

Each vacuum pump requires independent water pipes and an independent control box; Requires a circulating water pump, cooling tower, etc., to continuously replenish cooling water; In summer, the working liquid is in a high-temperature state for a long time, and the workshop is filled with water mist; accelerating the corrosion rate of the workshop's internal iron frames, various metal equipment, and metal steel beams; In the face of stringent environmental protection requirements, additional wastewater treatment equipment needs to be built. |

Highly integrated and highly intelligent, the machine front end is directly connected to the vacuum pipe and the power cord can be started and run, without the need for a foundation or other equipment. Under special operating conditions, additional pre-filtration equipment is required. |

|

Mechanical Efficiency |

General efficiency is around 30%; The water ring vacuum pump calibration is based on a 15℃ water temperature and 100% relative humidity intake, with the maximum pumping speed. Generally, when the cooling water temperature is higher than 15℃, the pumping speed is only 60-80% of the calibrated value. |

General efficiency is around 30%; Energy saving rate can reach 25%-50%.

|

Core Technology of Integrated Screw Vacuum Pump

The SQGH series energy-saving screw vacuum pump adopts a new generation of screw profiles, with screw rotor tooth profile precision superior to the industry, and light load operation.

The extraordinary integrated screw mainframe structure, with direct motor drive and no transmission loss, allows you to achieve nearly 100% transmission efficiency!

Vector frequency conversion control, rapid response, reasonable distribution of current values, and even better torque improvement effect.

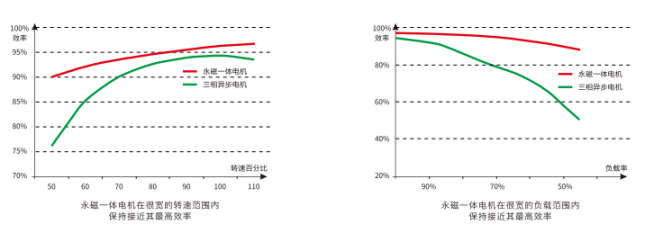

Full Series Permanent Magnet Frequency Conversion Technology

The SQGH micro-oil screw vacuum pump adopts an integrated permanent magnet frequency conversion dedicated motor, which greatly improves the efficiency of the drive motor, thus achieving energy saving.

√ Using high coercivity, high-temperature permanent magnets to ensure no demagnetization at 150℃;

√ Oversized torque design, one times the torque of a conventional 3000 rpm permanent magnet motor;

√ Stepless speed regulation, wide frequency modulation speed range, weak magnetic control is twice that of a general permanent magnet motor, easy frequency conversion control, good dynamic response performance, can quickly respond to a wide range of adjustments, and can also precisely adjust and control the vacuum pump;

√ Frequency conversion adjustment start, smooth start, reducing the impact on the power grid;

√ Super first-class energy efficiency, motor efficiency up to 98% or more;

√ High efficiency factor of 98% or more, reducing the customer's power grid pressure, maintaining power grid quality, and reducing the apparent current of the equipment.

Component Introduction

Integrated screw mainframe:

Direct motor drive, no transmission loss, and reduced transmission failures.

Permanent magnet frequency conversion control, rapid response, and high torque.

Axial flow fan: low power consumption, fast heat dissipation. Stable, reliable, energy-saving and environmentally friendly.

Sound insulation cover:

Significantly reduces noise through sound reflection from sound-absorbing foam and metal plates.

Reduces the cost of sound insulation equipment in the vacuum pump room.

Integrated Frequency Converter Drive:

Electrical cabinet with fully integrated frequency converter: no additional engineering and installation required.

Specially selected drive components: parameter settings can precisely achieve higher efficiency.

Optimized component selection.

Reduced installation costs.

Microcomputer Controller:

Integrated vacuum pump control system.

Displays the overall system performance status, proactively prompts maintenance information, and provides fault and safety shutdown warnings.

Dedicated intake valve:

Automatically controls the opening to ensure the host oil injection amount and lubrication oil circulation.

Ultra-low oil path loss, overall efficiency improvement.

Normally open solenoid valve control, emergency stop automatic closure, prevents oil injection.

Oil-gas separator tank:

Using a better flow rate and structural design, the oil content is ≤3ppm.

Easy maintenance.

Air filter: Patented design, fully enclosed structure, high filtration grade, ensures vacuum maintenance. Long service life, extends maintenance intervals.

Technical parameters

|

Model |

Motor power (kW) |

Flow rate (㎥/h) |

Ultimate vacuum (-Kpa) |

Inlet size |

Outlet size |

Dimensions (mm) |

Weight (kg) |

|

SQGH-7.5PM |

7.5 |

588 |

99.97 |

DN80 |

DN65 |

1500*880*1460 |

805 |

|

SQGH-11PM |

11 |

690 |

99.97 |

DN100 |

DN65 |

1850*920*1490 |

1040 |

|

SQGH-15PM |

15 |

876 |

99.97 |

DN100 |

DN65 |

||

|

SQGH-18.5PM |

18.5 |

1062 |

99.94-99.92 |

DN150 |

DN100 |

2000*1000*1670 |

1280 |

|

SQGH-22PM |

22 |

1320 |

99.94-99.92 |

DN150 |

DN100 |

||

|

SQGH-30PM |

30 |

1620 |

99.94-99.92 |

DN150 |

DN100 |

2300*1120*1827 |

1910 |

|

SQGH-37PM |

37 |

1812 |

99.94-99.92 |

DN150 |

DN100 |

||

|

SQGH-45PM |

45 |

2640 |

99.94-99.92 |

DN200 |

DN150 |

2860*1650*2114 |

3500 |

|

SQGH-55PM |

55 |

3180 |

99.94-99.92 |

DN200 |

DN150 |

||

|

SQGH-75PM |

75 |

4500 |

99.94-99.92 |

DN250 |

DN200 |

3300*2250*2350 |

5200 |

|

SQGH-90PM |

90 |

5400 |

99.94-99.92 |

DN250 |

DN200 |

Note:

1. Technical parameters are subject to change without further notice.

2. The above are the recommended models according to industry standards; custom orders are accepted if special requirements exist.

3. Please contact our sales staff for the delivery time of custom-made special models and power supplies.

Product advantages

Shandong Shengquan Power Equipment Co., Ltd. is a comprehensive manufacturer engaged in research and development, design, production, and sales. At present, it has a 12000 square meter factory building, including a large production workshop, exhibition hall, and quality testing laboratory. We have multiple mechanical engineering designers and an experienced team of employees and managers. Our production philosophy is based on quality standard technology research and development, and we strive to improve and refine our production processes. We strictly control product quality to ensure that our products are durable and corrosion-resistant.

Fast

High flow rate, shortened vacuum extraction time

Stable and reliable

Even under harsh industrial extreme application conditions, the entire machine is equipped with an automatic air supply system with a full flow range, which can maintain stable operation

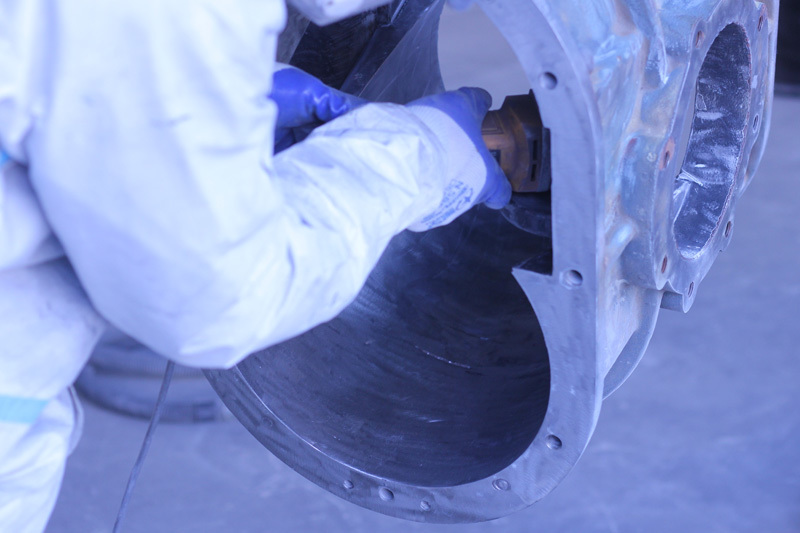

Quality anti-corrosion process

It is durable and aesthetically pleasing, using high-quality materials and advanced technology to ensure that the anti-corrosion layer is strong and durable, and the protective effect reaches the best state

Low carbon emissions

No need for water, no pollution at the discharge outlet, no waste oil discharge, and low electricity consumption.

Energy conservation

Variable frequency automatic control, worry free production. Set a fixed point to control the vacuum degree, and simply provide the vacuum degree to match the corresponding pumping speed, saving energy and electricity; Compared to water ring vacuum pumps, the isomorphic range can save more than 30%~70% energy

Low cost

The whole machine is integrated and can be used by wiring. At the same time, the lubricating oil circulates internally, resulting in low maintenance costs in the later stage.

Plant equipment

Application

Innovation breaks through stable quality, implements management to improve efficiency. The products can be used in hospitals, foam industry, furniture and wood industry, tire industry, paper and plastic industry, pharmacy, glass industry, casting, pipeline industry LED、 Ceramics, electronic semiconductors, low-carbon environmental protection, aerospace and military industry, universal energy-saving hospitals, foam industry, furniture and wood industry, tire industry, paper and plastic industry, pharmaceutical industry, glass industry, casting industry, pipeline industry LED、 Industries such as ceramics, electronic semiconductors, low-carbon environmental protection, aerospace and military industries, and promoting energy conservation.

Medical treatment

Aerospace Military Industry

Casting pipeline

Electronic industry

Petrochemical industry

Biopharmaceutical

Video

Installation video of foam plant 1

Installation video of foam plant

Customer Case

Product delivery

Product video

Anti-corrosion process

Got a problem?

Get in touch with us!

Contact info

Email: info@asorber.cn

Whatsapp: 86 15966548741

Phone: +86 15805353012

Address: Wuning Street, Muping District, Yantai City, Shandong Province, China 264118