Product Introduction

Product Features:

★ Low energy consumption: The oil-free screw blower is based on the principle of adiabatic compression, with a total efficiency exceeding 75%, saving 20%-35% more energy than the Roots blower. Higher exhaust pressure and lower pressure pulsation;

★ Low noise: The aerodynamic noise of the screw rotor is small, with stable output, eliminating the sudden release of internal air. The wave-shaped inlet and outlet reduce airflow fluctuations, and the blower noise is less than that of traditional blowers;

★ Intelligent: Intelligent PLC control, remote control. Multiple communication methods, convenient operation and management, interlocking control, and early warning prompts;

★ Low cost: The optimized structural design ensures the product's durability with less consumption, while the unit runs smoothly with a small load and does not require special infrastructure. Achieving greater customer benefits;

★ Stable and reliable: High-temperature performance test, durable and reliable, multi-channel air intake, overcoming various operating conditions.

Energy Efficiency Comparison---------More intuitive economic benefits

Working Principle of Roots Blower

★ Inlet begins

★ Inlet ends, volume remains unchanged

★ Gas is compressed and discharged externally under back pressure

Working Principle of Screw Blower

★ Inlet begins

★ Inlet ends, compression begins

★ During compression, compression ends, and exhaust begins

Energy Efficiency Comparison Chart between Traditional Roots Blowers and Oil-Free Screw Blowers

Compared with traditional blowers, the SQ-SL/FL/GS series has the following advantages:

★ Low energy consumption: The oil-free screw blower is based on the principle of adiabatic compression, with a total efficiency exceeding 75%, saving 20%-35% more energy than the Roots blower. Higher exhaust pressure and lower pressure pulsation.

★ Low noise: The aerodynamic noise of the screw rotor is small, with stable output, eliminating the sudden release of internal air. The wave-shaped inlet and outlet reduce airflow fluctuations, and the blower noise is less than that of traditional blowers.

★ Intelligent: Intelligent remote control, multiple communication methods, and convenient operation and management.

★ Low cost: The optimized structural design ensures the product's durability with less consumption, while the unit runs smoothly with a small load and does not require special infrastructure. Achieving greater customer benefits.

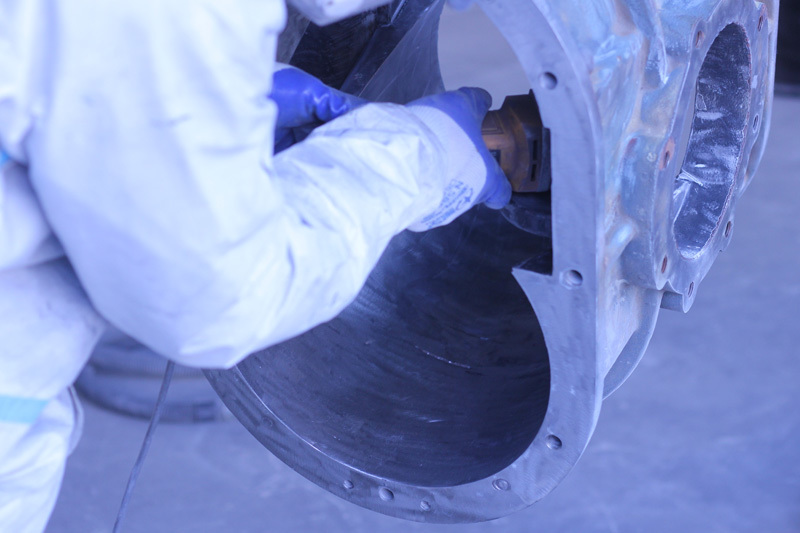

Component Introduction

★ Screw main unit: The bearing adapts to constantly changing loads, providing high flexibility and efficiency; ensuring smooth production processes;

★ Air filter: High-quality intake filters provide high filtration levels, high process reliability, and high energy efficiency; long service life, extending maintenance intervals;

★ Sound insulation cover: Significantly reduces noise through sound absorption foam and metal plate sound reflection; reduces the cost of sound insulation equipment in the blower room; all equipment can be inspected by opening the sound insulation cover;

★ Integrated frequency converter driver: Electrical cabinet with fully integrated frequency converter, requiring no additional engineering or installation; specially selected drive components: parameter settings can accurately achieve higher efficiency; optimized component selection reduces installation costs;

★ Microcomputer controller: Integrated blower control system; displays the overall system performance status, proactively prompts maintenance information, and provides fault and safety shutdown alerts;

★ Oil system: Advanced oil system design integrates oil pump, oil cooler, and filter; low oil temperature, long service life of bearings and gears;

★ Inlet and outlet silencers: Inlet and outlet are installed in fixed positions for easy pipe connection; all grilles are lined to reduce noise; independent cooling airflow avoids recirculation;

★ Permanent magnet motor: Low speed, high torque; independent fan cooling ensures stable motor operation.

SQSL Permanent Magnet Frequency Conversion Screw Blower (Self-lubricating)

| Model |

Motor Power (kW) |

Exhaust Pressure (bar) |

Flow Rate (㎥/min) |

Start-up Method |

Outlet Size |

Overall Dimensions (L*W*H) mm |

Unit Total Weight (kg) |

| SQSL-11-0.5 |

11 |

0.5 |

9.1 |

Permanent Magnet Variable Frequency |

DN150 |

1945*1100*1495 |

1000 |

| SQSL-11-0.9 |

0.9 |

5.7 |

|||||

| SQSL-15-0.5 |

15 |

0.5 |

10.3 |

||||

| SQSL-15-0.9 |

0.9 |

8.4 |

|||||

| SQSL-19-0.5 |

18.5 |

0.5 |

16.9 |

2200*1250*1650 |

1500 |

||

| SQSL-19-0.9 |

0.9 |

9.5 |

1945*1100*1495 |

1000 |

|||

| SQSL-22-0.5 |

22 |

0.5 |

21.2 |

DN150 |

2200*1250*1650 |

1500 |

|

| SQSL-30-0.5 |

30 |

0.5 |

25.5 |

||||

| SQSL-30-0.9 |

0.9 |

19.6 |

|||||

| SQSL-37-0.5 |

37 |

0.5 |

36.9 |

DN250 |

2750*1300*1870 |

2100 |

|

| SQSL-37-0.9 |

0.9 |

25.2 |

DN150 |

2200*1250*1650 |

1500 |

||

| SQSL-45-0.5 |

45 |

0.5 |

45.1 |

DN250 |

2750*1300*1870 |

2100 |

|

| SQSL-45-0.9 |

0.9 |

31.9 |

2100 |

||||

| SQSL-55-0.5 |

55 |

0.5 |

57.2 |

3000*1400*2100 |

3350 |

||

| SQSL-55-0.9 |

0.9 |

39.4 |

2750*1300*1870 |

2100 |

|||

| SQSL-75-0.5 |

75 |

0.5 |

73.6 |

DN300 |

3300*1700*2250 |

4000 |

|

| SQSL-75-0.9 |

0.9 |

56.4 |

DN250 |

2750*1300*1870 |

2100 |

||

| SQSL-90-0.5 |

90 |

0.5 |

87 |

DN300 |

3300*1700*2250 |

4000 |

|

| SQSL-90-0.9 |

0.9 |

65.5 |

DN250 |

3000*1400*2100 |

3350 |

| Model |

Motor Power (kW) |

Exhaust Pressure (bar) |

Flow Rate (㎥/min) |

Start-up Method |

Outlet Size |

Overall Dimensions (L*W*H) mm |

Unit Total Weight (kg) |

| SQSL-15-1.0 |

15 |

1.0 |

7.7 |

Permanent Magnet Variable Frequency |

DN150 |

1945*1100*1495 |

1000 |

| SQSL-15-1.4 |

1.4 |

5.4 |

|||||

| SQSL-19-1.0 |

18.5 |

1.0 |

9.4 |

||||

| SQSL-19-1.4 |

1.4 |

6.4 |

|||||

| SQSL-22-1.4 |

22 |

1.4 |

8.7 |

||||

| SQSL-30-1.0 |

30 |

1.0 |

15.3 |

2200*1250*1650

|

1500 |

||

| SQSL-37-1.0 |

37 |

1.0 |

21.6 |

||||

| SQSL-37-1.4 |

1.4 |

14.1 |

|||||

| SQSL-45-1.0 |

45 |

1.0 |

24.5 |

||||

| SQSL-45-1.4 |

1.4 |

17 |

|||||

| SQSL-55-1.0 |

55 |

1.0 |

36.3 |

DN250 |

2750*1300*1870

|

2100 |

|

| SQSL-75-1.0 |

75 |

1.0 |

49.1 |

||||

| SQSL-75-1.4 |

1.4 |

38 |

|||||

| SQSL-90-1.0 |

90 |

1.0 |

65.3 |

3000*1400*2100 |

3350 |

||

| SQSL-90-1.0 |

1.4 |

45.8 |

2750*1300*1870 |

2100 |

|||

| SQSL-110-1.0 |

110 |

1.0 |

69.1 |

DN300 |

3300*1700*2250 |

4000 |

|

| SQSL-110-1.4 |

1.4 |

57.3 |

DN400 |

3000*1400*2100 |

3350 |

||

| SQSL-132-1.0 |

132 |

1.0 |

85.9 |

DN300 |

3300*1700*2250

|

4000 |

|

| SQSL-160-1.0 |

160 |

1.0 |

98.9 |

||||

| SQSL-160-1.4 |

1.4 |

78.3 |

|||||

| SQSL-185-1.0 |

185 |

1.4 |

94.2 |

SQFS Permanent Magnet Frequency Conversion Screw Blower (Forced Lubrication)

| Model |

Motor Power (kW) |

Exhaust Pressure (bar) |

Flow Rate (㎥/min) |

Start-up Method |

Outlet Size |

Overall Dimensions (L*W*H) mm |

Unit Total Weight (kg) |

| SQFL-22-1.5 |

22 |

1.5 |

7 |

Permanent Magnet Variable Frequency

|

DN150

|

1945*1100*1495 |

1000 |

| SQFL-22-2.0 |

2.0 |

4.6 |

|||||

| SQFL-30-1.5 |

30 |

1.5 |

7.9 |

||||

| SQFL-30-2.0 |

2.0 |

7.4 |

|||||

| SQFL-45-1.5 |

45 |

1.5 |

15.9 |

2200*1250*1650 |

1500 |

||

| SQFL-55-1.5 |

55 |

1.5 |

23 |

||||

| SQFL-55-2.0 |

2.0 |

15.7 |

|||||

| SQFL-75-1.5 |

75 |

1.5 |

34.7 |

DN250 |

2750*1300*1870 |

2100 |

|

| SQFL-75-2.0 |

2.0 |

21.9 |

DN150 |

2200*1250*1650 |

1500 |

||

| SQFL-90-1.5 |

90 |

1.5 |

40.3 |

DN250 |

2750*1300*1870 |

2100 |

|

| SQFL-90-2.0 |

2.0 |

31.6 |

|||||

| SQFL-110-1.5 |

110 |

1.5 |

44.9 |

||||

| SQFL-110-2.0 |

2.0 |

38.9 |

|||||

| SQFL-132-1.5 |

132 |

1.5 |

62.4 |

3000*1400*2100 |

3350 |

||

| SQFL-132-2.0 |

2.0 |

43.3 |

2750*1300*1870 |

2100 |

|||

| SQFL-160-1.5 |

160 |

1.5 |

64.6 |

3000*1400*2100 |

3350 |

||

| SQFL-160-2.0 |

2.0 |

57.1 |

|||||

| SQFL-185-1.5 |

185 |

1.5 |

82.5 |

DN300 |

3300*1700*2250 |

4000 |

|

| SQFL-200-1.5 |

200 |

1.5 |

91.9 |

DN300 |

3300*1700*2250 |

4000 |

|

| SQFL-220-2.0 |

220 |

2.0 |

84.1 |

||||

| SQFL-250-2.0 |

250 |

2.0 |

93.3 |

SQGS Permanent Magnet Frequency Conversion Screw Blower

| Model |

Motor Power (kW) |

Exhaust Pressure (bar) |

Flow Rate (㎥/min) |

Start-up Method |

Outlet Method |

Overall Dimensions (L*W*H) mm |

Unit Total Weight (kg) |

| SQGS-22 |

22 |

0.5-1.0 |

12.3 |

Permanent Magnet Variable Frequency |

DN150 |

1780*780*1430 |

600 |

| SQGS-30 |

30 |

0.5-1.0 |

16.7 |

1780*780*1440 |

645 |

||

| SQGS-37 |

37 |

0.5-1.0 |

20.2 |

1780*780*1485 |

775 |

||

| SQGS-45 |

45 |

0.5-1.0 |

27.7 |

DN200 |

1914*935*1760 |

1015 |

|

| SQGS-55 |

55 |

0.5-1.0 |

36.1 |

1100 |

|||

| SQGS-75 |

75 |

0.5-1.0 |

47.1 |

DN250 |

2200*1000*1850 |

1440 |

|

| SQGS-90 |

90 |

0.5-1.0 |

59.3 |

2200*1100*1850 |

1550 |

Product advantages

Shandong Shengquan Power Equipment Co., Ltd. is a comprehensive manufacturer engaged in research and development, design, production, and sales. At present, it has a 12000 square meter factory building, including a large production workshop, exhibition hall, and quality testing laboratory. We have multiple mechanical engineering designers and an experienced team of employees and managers. Our production philosophy is based on quality standard technology research and development, and we strive to improve and refine our production processes. We strictly control product quality to ensure that our products are durable and corrosion-resistant.

Fast

High flow rate, shortened vacuum extraction time

Stable and reliable

Even under harsh industrial extreme application conditions, the entire machine is equipped with an automatic air supply system with a full flow range, which can maintain stable operation

Quality anti-corrosion process

It is durable and aesthetically pleasing, using high-quality materials and advanced technology to ensure that the anti-corrosion layer is strong and durable, and the protective effect reaches the best state

Low carbon emissions

No need for water, no pollution at the discharge outlet, no waste oil discharge, and low electricity consumption.

Energy conservation

Variable frequency automatic control, worry free production. Set a fixed point to control the vacuum degree, and simply provide the vacuum degree to match the corresponding pumping speed, saving energy and electricity; Compared to water ring vacuum pumps, the isomorphic range can save more than 30%~70% energy

Low cost

The whole machine is integrated and can be used by wiring. At the same time, the lubricating oil circulates internally, resulting in low maintenance costs in the later stage.

Plant equipment

Application

Innovation breaks through stable quality, implements management to improve efficiency. The products can be used in hospitals, foam industry, furniture and wood industry, tire industry, paper and plastic industry, pharmacy, glass industry, casting, pipeline industry LED、 Ceramics, electronic semiconductors, low-carbon environmental protection, aerospace and military industry, universal energy-saving hospitals, foam industry, furniture and wood industry, tire industry, paper and plastic industry, pharmaceutical industry, glass industry, casting industry, pipeline industry LED、 Industries such as ceramics, electronic semiconductors, low-carbon environmental protection, aerospace and military industries, and promoting energy conservation.

Medical treatment

Aerospace Military Industry

Casting pipeline

Electronic industry

Petrochemical industry

Biopharmaceutical

Video

Installation video of foam plant 1

Installation video of foam plant

Customer Case

Product delivery

Product video

Anti-corrosion process

Got a problem?

Get in touch with us!

Contact info

Email: info@asorber.cn

Whatsapp: 86 15966548741

Phone: +86 15805353012

Address: Wuning Street, Muping District, Yantai City, Shandong Province, China 264118