Product Introduction

Features of oil-free variable frequency screw vacuum pump:

★ The application of a new, self-owned patented energy-saving screw tooth profile provides you with a greater competitive advantage in the industry;

★ The new, self-owned patented vacuum-specific sealing structure design gives the pump a longer lifespan and reduces maintenance costs;

★ A food-grade coating solution jointly developed by multiple units can significantly reduce gas loss, prevent rust and corrosion, and improve efficiency at the same time;

★ Dry, oil-free cavity design, can operate at a constant high pumping speed, stable negative pressure unaffected by operating temperature;

★ Mainly replaces water ring pumps and vane pumps, and can also be used as a pre-stage pump for Roots pumps, with obvious environmental protection and energy-saving effects;

★ Ready to use: Integrated design, all components are installed in one box, simple maintenance, low noise;

★ Safe and reliable: Built-in air replenishment device, can protect the entire machine from safe operation under extreme conditions according to changes in the host exhaust temperature;

★ One-button operation: Automated control, simple operation, operation records, automatic alarm;

★ Stronger negative pressure: Oil immersion station with built-in oil mist separation function, auxiliary shell oil cooling, higher and more stable negative pressure;

★ Environmental protection without worries: Dry operation, no other medium required, realizing oil-free pollution, no wastewater discharge, energy saving and emission reduction;

★ High efficiency and energy saving: Compared with water ring pumps and Roots pumps of the same vacuum pump, energy saving is about 20%-40%, and 50%-100% linear stepless frequency control can be provided to reduce unnecessary power consumption during equipment operation;

★ Corrosion protection design: Parts in contact with the gas to be extracted can choose various anti-corrosion coatings to resist medium corrosion.

Component Introduction

1. Perfect control system

It can automatically adjust the operating frequency according to the set pressure, only providing peak speed when needed in industry, meeting the requirements of different operating conditions, and further reducing energy consumption and maintenance costs. With a microcomputer control system, the operating status and parameters of the vacuum pump can be monitored remotely, and the causes can be analyzed and problems quickly solved based on remote fault warnings and alarms, providing technical support for the long-term reliable operation of the equipment.

2. Permanent magnet synchronous motor power system

The ultra-high-efficiency motor is equipped with precision bearings, low speed, low noise, stepless;

The large adjustment range brings greater energy-saving space.

3. Noise reduction system

In practical applications, the host exhaust will produce strong noise, which has a great impact on people's production and life, so it is urgent to control the noise. A high-efficiency silencer can reduce the noise emitted from the host to a reasonable range for environmental life.

4. Safety protection system

A complete set of safety protection components for the whole machine. When the exhaust temperature of the whole machine is too high, or the vacuum degree of the whole machine exceeds the set value, the solenoid valve in the protection system is opened to prevent damage to the host, and a simple structure is used to ensure the safe use of the host.

5. Heat dissipation system

Heat dissipation system

A safe and stable heat dissipation system controls the oil temperature within a certain range, ensuring that the oil temperature in the entire system is always at an appropriate temperature, so that the system runs more stably.

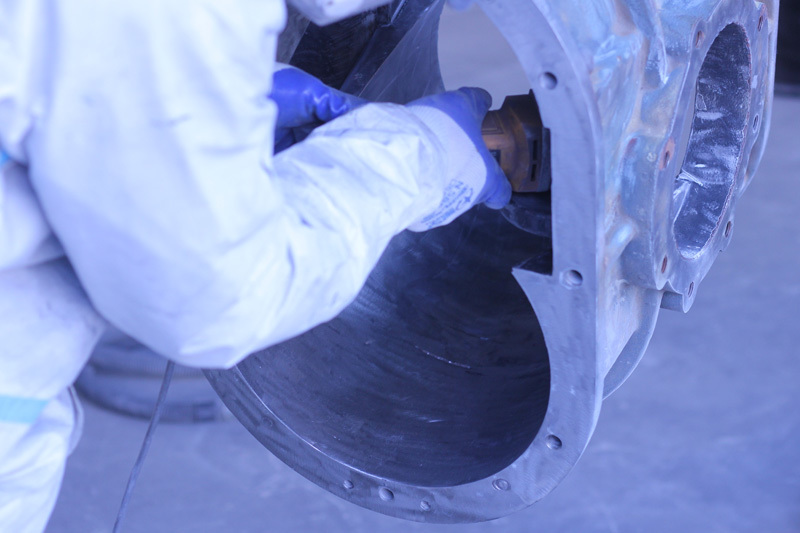

6. Host system

It adopts a new type of energy-saving screw rotor gear independently developed, which is more energy-saving and reliable. The vacuum-specific sealing structure design gives the pump a longer lifespan and reduces maintenance costs. The food-grade coating solution jointly developed by multiple units can greatly reduce gas loss, prevent rust and corrosion, and improve efficiency at the same time. The dry, oil-free cavity design can operate at a constant high pumping speed, with stable negative pressure unaffected by operating temperature. Replacing negative pressure Roots blower and water ring pump applications, with obvious environmental protection and energy-saving effects.

7. Cooling and lubricating oil system

The oil tank structure combines the oil mist separator and the oil pump motor into one, with a high degree of integration and small space occupied inside the box. In addition to preliminary separation through the oil mist separation core structure in the oil mist separator structure, a breathable cap is also added for a second mechanical separation, making the oil mist separation more thorough, and the oil content in the discharged air is lower, and the impact on the environment is smaller. At the same time, combined with the internal simple oil circuit system, the design of the whole machine is more concise and clear.

Technical Parameters

| Motor power (kW) |

Model |

Maximum pumping speed (m³/min) |

Ultimate pressure (-kPa) |

Dimensions (L*W*H mm) |

Inlet size |

Outlet size |

| 7.5 |

SQDH-7.5PM-I |

3.50 |

70 |

1750*1010*1280 |

DN100 |

DN150 |

| 7.5 |

SQDH-7.5PM-II |

5.00 |

70 |

1750*1010*1280 |

DN100 |

DN150 |

| 11 |

SQDH-11PM-I |

7.17 |

70 |

1750*1010*1280 |

DN100 |

DN150 |

| 11 |

SQDH-11PM-II |

8.33 |

70 |

1750*1010*1280 |

DN100 |

DN150 |

| 18.5 |

SQDH-18.5PM |

11.67 |

70 |

1950*1040*1428 |

DN200 |

DN150 |

| 22 |

SQDH-22PM-I |

15.50 |

70 |

1950*1040*1428 |

DN200 |

DN150 |

| 22 |

SQDH-22PM-II |

18.33 |

70 |

1950*1040*1428 |

DN200 |

DN150 |

| 30 |

SQDH-30PM |

25.00 |

70 |

2040*1400*1695 |

DN200 |

DN200 |

| 37 |

SQDH-37PM |

28.33 |

70 |

2040*1400*1695 |

DN200 |

DN200 |

| 45 |

SQDH-45PM-I |

36.67 |

70 |

2040*1400*1695 |

DN200 |

DN200 |

| 45 |

SQDH-45PM-II |

40.00 |

70 |

2040*1400*1695 |

DN200 |

DN200 |

| 55 |

SQDH-55PM |

45.00 |

70 |

2040*1400*1695 |

DN200 |

DN200 |

| 75 |

SQDH-75PM |

61.67 |

70 |

2150*1500*1798 |

DN300 |

DN250 |

| 90 |

SQDH-90PM |

75.00 |

70 |

2510*1800*2200 |

DN400 |

DN300 |

| 110 |

SQDH-110PM |

95.00 |

70 |

2510*1800*2200 |

DN400 |

DN300 |

| 160 |

SQDH-160PM |

130.00 |

70 |

3300*1800*2550 |

DN500 |

DN450 |

| 180 |

SQDH-180PM |

170.00 |

70 |

3300*1800*2550 |

DN500 |

DN450 |

| 200 |

SQDH-200PM |

190.00 |

70 |

3300*1800*2550 |

DN500 |

DN450 |

Note:

1. Technical parameters are subject to change without further notice.

2. The above are recommended models based on industry standards; customized options are available upon request.

3. Please contact our sales representatives for delivery times of customized models and power supplies.

Product advantages

Shandong Shengquan Power Equipment Co., Ltd. is a comprehensive manufacturer engaged in research and development, design, production, and sales. At present, it has a 12000 square meter factory building, including a large production workshop, exhibition hall, and quality testing laboratory. We have multiple mechanical engineering designers and an experienced team of employees and managers. Our production philosophy is based on quality standard technology research and development, and we strive to improve and refine our production processes. We strictly control product quality to ensure that our products are durable and corrosion-resistant.

Fast

High flow rate, shortened vacuum extraction time

Stable and reliable

Even under harsh industrial extreme application conditions, the entire machine is equipped with an automatic air supply system with a full flow range, which can maintain stable operation

Quality anti-corrosion process

It is durable and aesthetically pleasing, using high-quality materials and advanced technology to ensure that the anti-corrosion layer is strong and durable, and the protective effect reaches the best state

Low carbon emissions

No need for water, no pollution at the discharge outlet, no waste oil discharge, and low electricity consumption.

Energy conservation

Variable frequency automatic control, worry free production. Set a fixed point to control the vacuum degree, and simply provide the vacuum degree to match the corresponding pumping speed, saving energy and electricity; Compared to water ring vacuum pumps, the isomorphic range can save more than 30%~70% energy

Low cost

The whole machine is integrated and can be used by wiring. At the same time, the lubricating oil circulates internally, resulting in low maintenance costs in the later stage.

Plant equipment

Application

Innovation breaks through stable quality, implements management to improve efficiency. The products can be used in hospitals, foam industry, furniture and wood industry, tire industry, paper and plastic industry, pharmacy, glass industry, casting, pipeline industry LED、 Ceramics, electronic semiconductors, low-carbon environmental protection, aerospace and military industry, universal energy-saving hospitals, foam industry, furniture and wood industry, tire industry, paper and plastic industry, pharmaceutical industry, glass industry, casting industry, pipeline industry LED、 Industries such as ceramics, electronic semiconductors, low-carbon environmental protection, aerospace and military industries, and promoting energy conservation.

Medical treatment

Aerospace Military Industry

Casting pipeline

Electronic industry

Petrochemical industry

Biopharmaceutical

Video

Installation video of foam plant 1

Installation video of foam plant

Customer Case

Product delivery

Product video

Anti-corrosion process

Got a problem?

Get in touch with us!

Contact info

Email: info@asorber.cn

Whatsapp: 86 15966548741

Phone: +86 15805353012

Address: Wuning Street, Muping District, Yantai City, Shandong Province, China 264118